Impact of Laser Cleaning on Environmental Protection in China

Great strides made by China, a manufacturing powerhouse recognized by the world, towards industrialization has been accompanied by lingering problems such as environmental degradation and industrial pollution. Stricter laws and regulations on environmental protection in recent years have forced some businesses to shut down for overhaul. But an approach of one-fit-all in this environmental campaign has caused negative impact on the economy and the key should be transforming conventional production models that have been polluting the environment. Technological advancement has enabled people to explore all kinds of technologies beneficial to the environment with laser cleaning included. It is an emerging cleaning technology applied to the workpiece surface in the past decade, gradually replacing traditional cleaning techniques for its advantages and irreplaceable stance.

Traditional cleaning approaches include mechanical cleaning, chemical cleaning and ultrasonic cleaning. The mechanical cleaning is about scratching, rubbing, brushing and sandblasting dirt from the surface. The wet chemical cleaning is to clean the surface by spraying or sprinkling organic cleaning agents, after immersing the item into agents or through high-frequent vibration. Ultrasonic cleaning is to clean components in vibration produced by ultrasonic waves after immersing them into cleaning agents. These three methods have taken a dominant position in the domestic cleaning market but all lead to pollution to different extents, thus their applications suffer from great restrictions when requirements of environmental protection and high precision are considered.

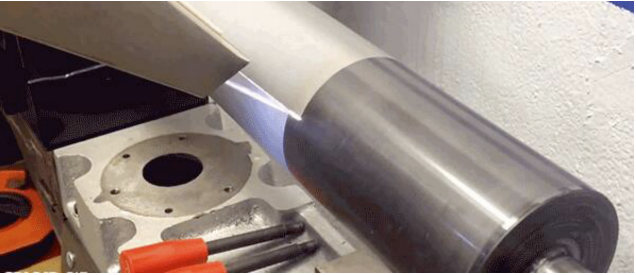

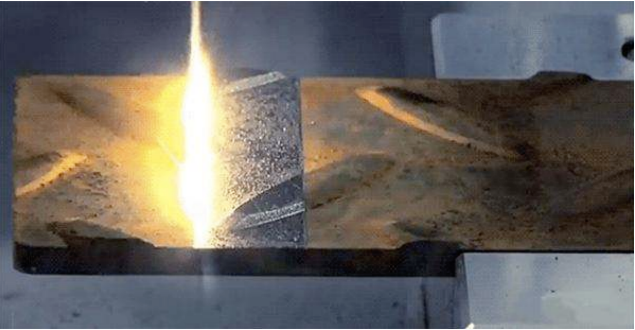

Laser cleaning is a technological process in which laser beam of high energy and frequency is projected onto the surface to evaporate or peel away dirt, rust or coating so that the surface attachment or coating could be rapidly and effectively removed. It is characterized by concentrating in one direction, monochromaticity, high coherence and brightness. Focusing lens and Q switch concentrate energy onto a small spatial scope within a certain period of time.

Conventional cleaning technologies including chemical cleaning and mechanical polishing are far from satisfying requirements of industrialized production as a result of the progress of high-end manufacturing and demanding environmental protection. The backwardness of cleaning technologies has prevented a part of important industries from normal operation in China. Against the background of rapid development of high-end manufacturing in China, laser cleaning representing green and high-efficient manufacturing, enjoys a broad market prospect.

Compared with traditional cleaning approaches, this green cleaning technique has unparalleled advantages: no need of any chemical agents or cleaning fluids; residues after cleaning are mainly solid powders that are small in size, easy for storage and recyclable by adsorption. These wastes don’t react under photochemical conditions, neither produce noise nor pollutants, which means that health of operators are ensured and the cleaning process is easy to be automatically and remotely controlled.

Wide Application of Laser Cleaning in Multiple Areas

Status Quo and Prospect for the Industry of Laser Cleaning

Application of laser cleaning has been promoted in Europe for years with products already in place, whereas in China, it has only made a start. This disparity is mainly explained by the difficulties in wide application because of high cost. In spite of some achievements obtained within a short period thanks to efforts made in R&D and equipment development, China still follows footprints led by advanced countries and lags behind by a large margin.

In 2010, the Laser Fusion Center of the Chinese Academy of Engineering Physics (CAEP) made the first attempt to develop laser cleaning equipment in China and later successfully applied it in cleaning the Yungang Grottoes, stone walls, statues, murals and other cultural relics. The following years have celebrated an increasing number of papers on laser cleaning technique contributed by all kinds of research institutes. More attention has been paid by the industry to laser cleaning and businesses are spurred in developing laser cleaning equipment.

The layout of laser cleaning industry in China features 4 clusters of the Pearl River Delta, the Yangtze River Delta, Central China and the Bohai Rim. Many representative businesses have engraved their names on the stela such as Han’s Laser, Hero Laser, Max Photonics, China Space Sanjiang Research Institute (Wuhan), Raycus, Guoke Century Laser, ZKSX Laser, Dinai Lasers Technology and Ziyu Laser.

Laser cleaning boosts remarkable economic benefit and broad market prospect as a green and highly efficient cleaning technology. Lack in R&D of laser cleaning could be compensated by commercialization if whole sets of laser cleaning equipment were developed based on current laser technology and put into production. This helps drive down costs and enhance popularity of laser cleaning. Updated process has the potential of reducing pollution from the root and actually contributes to environmental protection in China.

On the ground that huge potential values for laser cleaning, an advanced technology in laser manufacturing, in industrial application would be unlocked, vigorous input into laser cleaning is of strategic importance to raise competitiveness of high-end laser manufacturing technologies and equipment and in turn boosts social and economic development. In conclusion, ministries and departments of science and technology as well as environmental protection are expected to dish out more attention and support.